Description

Includes Motor and guards: 2hp, 3ph, 220/440v, 50/60Hz

Several motor configurations available

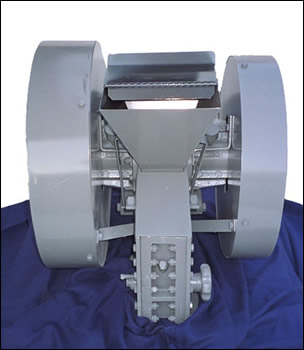

The upper end of the jaw travels in a circular path driven by the eccentric shaft. The lower end oscillates through a short arc described by the toggle. The resultant jaw action is a forward and downward motion relative to the stationary jaw that crushes the sample and forces its discharge.

Heavy bronze bearings are sealed against dust and dirt and are lubricated by grease cups, so that no special greasing tools are required. Bearings may be taken up for wear, reversed on the saft for more wear, and after long service, easily replaced.

Cleaning the Chipmunk Crusher is easily accomplished. The stationary jaw is easily lifted out of the frame to completely expose the inner parts for thorough brushing. Dropping the camlock handle anchors the jaw securely in position

The discharge opening between jaw can be adjusted to control crushed particle size by turning a hand wheel on the side of the crusher. The adjusting mechanism consists of wedge blocks operated by a screw. The blocks transmit crushing force from the jaw to the frame relieving all strain on the adjusting screw itself.

Jaw Capacity: 2 1/4″ x 3″

Drive Type: V-Belt Driven

RPM: 400

Capacity: 400 lbs. per hour

Crushers with motor include motor base and belt/flywheel guards.

Crushers without motor do not include motor base or belt/flywheel guards.

RECOMMENDED SPARE PARTS FOR NORMAL ONE (1) YEAR OPERATION OF VD CRUSHER

2 ea. VD-65 Toggle

2 ea. VD-70A Right Hand Bearing Split Bushing

2 ea. VD-70B Left Hand Bearing Split Bushing

2 ea. VD-82 Plate for Stationary Jaw

2 ea. VD-82A Plate for Stationary Jaw – Manganese

1 ea. VD-84 Adjusting Screw

2 ea. VD-85 Cheek Plate

2 ea. VD-86 Plate for Movable Jaw

2 ea. VD-86A Plate for Movable Jaw – Manganese

2 ea. VD-87 Spring Rod w/Wing Nut

2 ea. VD-88 Spring

1 set VD-132 V-Belts – matched set of 4

cross Reference # LC-34 and LC-34A

![[Most Recent Quotes from www.kitco.com]](https://www.kitconet.com/charts/metals/gold/t24_au_en_usoz_2.gif)

Reviews

There are no reviews yet.