Description

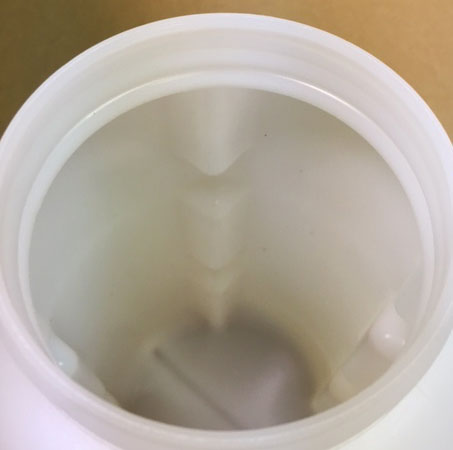

Wide mouth PP (polypropylene) bottle with integrated internal lifters. 3.5 liter capacity.

Typically used for cyanide agitation tests with 1000 grams of sample at 40% solids. Internal lifters aid in agitation and blending. Lifters are approximately 1/2″ high.

Also useful for mixing and blending ground pulp samples and other tests. Use with ceramic grinding media or steel balls for light duty grinding.

Bottles are rotated by a powered drive roll (usually with rubber covered rollers)- either fixed speed or variable speed depending on application.

Approximate dimensions: 11.5″ (292mm) x 5.5″ (140mm) diameter. Lid Opening: 3.5″ (90mm). Autoclavable.

See the lifter bottle in action at this video which shows the LIFTERBOTTLE versus a smooth walled bottle:

Rolling bottle leach tests are used in many types of laboratories. Historically, rolling bottle tests have been run in smooth walled bottles in which mixing of the solid with the solution is difficult and sometimes not existent.

After several years of development, Kappes, Cassiday & Associates has announced the LIFTERBOTTLE™, a three and one-half liter, wide mouth, PP bottle with integrated lifters cast into the walls of the bottle.

Applications for the LIFTERBOTTLE™:

Perform metallurgical test work to determine the leachability of an ore or ore product.

Eliminates the need for manual mixing.

Applications for the aggregate and asphalt industries.

Uses in cell biology and microbiology.

Cell and tissue agitation and growth.

Maintaining systems in suspension.

Mixing to maintain consistency in paints and adhesives.

Rock and mineral tumbling for polishing.

Typical usage:

A rolling bottle leach test is a common analytical test used in determining if a constituent can be extracted from a solid. As an analytical tool, a solution contacted with a solid in a rolling bottle leach test is one of the first tests an analytical chemist might utilize to determine the type and amount of leachable metals or other constituents present in a naturally occurring or by product material. The application of this analytical test type is widely used in a variety of analytical, environmental and geochemical/metallurgical laboratories.

Simply said, a rolling bottle test consists of a bottle filled with known amounts of solid material and a liquid. The solid material can be either a naturally occurring material or a man-made product that is sized according to the needs of the test work. The liquid can have either an acid, neutral or basic pH and will typically contain a specific constituent intended to enhance the leaching. In the most basic case, neutral water is used as the leaching solution. The sealed bottle is then rolled on laboratory rolls for a specific period of time. The test leach period can be short or long. At designated time intervals and/or at the end of the leaching period the solution is sampled and analyzed for the constituents of interest. The final solid residue material can be assayed as well for the constituents of interest so that a mass balance can be formulated and an extraction can be calculated.

Environmental characterization test work may employ a variety of leach conditions in rolling bottle tests to examine the possibility that a constituent might migrate from the solid into the surrounding soils, rocks or aquifers.

Geological type laboratories use rolling bottle roll tests as a first step in determining if a metal or non-metal can be extracted from either a primary or secondary mined product.

Historically, rolling bottle tests have been run in smooth walled bottles in which the thorough mixing of the solid with the solution is difficult if not sometimes nonexistent since the wetted material tends to slides along the smooth walls of the bottle rather than be constantly contacted with the solution.

A standardized bottle roll cyanidation test proceedure developed by KCA is available

Click to Download Cyanidation Test Proceedure

Also useful for lapidary polishing and tumbling which is a common method used to polish stones. Historically, tumbling has been performed in smooth walled and sometimes cost prohibitive tumbling drums. The lifterbottle is a 9 lb. equivalent bottle that is designed with proprietary lifting ridges on the sides to increase the efficiency of tumbling operations. The bottle is lightweight, easy to handle, and easy to thoroughly clean. Because of its low cost, multiple bottles can be dedicated to each stage of the polishing process.

![[Most Recent Quotes from www.kitco.com]](https://www.kitconet.com/charts/metals/gold/t24_au_en_usoz_2.gif)

Reviews

There are no reviews yet.